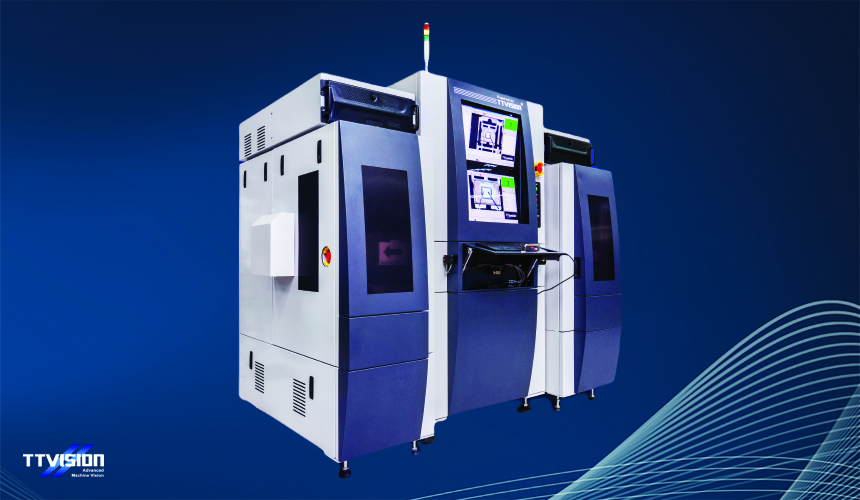

Wirebond AOI Machine

Wirebond AOI Machine

Description

The Wirebond AOI Machine stands as a cutting-edge solution for inspecting critical components in semiconductor manufacturing, offering advanced features for defect detection and precise parameter measurement in wirebond, die, and epoxy applications.

Features

- 3D Profiling Technology:

The Wirebond AOI Machine incorporates state-of-the-art 3D profiling technology, enabling detailed and accurate inspection of wirebond, die, and epoxy features for enhanced defect detection. - Camera Resolution up to 67 megapixels:

With an impressive camera resolution of up to 67 megapixels, the machine ensures high-quality imaging for precise inspection and analysis of wirebond structures. - Inspects Wirebond, Die, and Epoxy Defects:

The machine is designed to comprehensively inspect wirebond connections, die attachment, and epoxy application, ensuring the detection of various defects in these critical areas. - Inspect Gold, Aluminum, Copper, and Silver Wires:

Offering versatility, the system is capable of inspecting wirebonds made from various materials, including gold, aluminum, copper, and silver, ensuring compatibility with diverse manufacturing processes. - Measure Ball, Wedge, Stitch, and Loop Parameters:

The Wirebond AOI Machine goes beyond visual inspection by precisely measuring essential parameters such as ball, wedge, stitch, and loop characteristics, providing comprehensive data for quality assessment. - Modular and Scalable Design:

Featuring a modular and scalable design, the machine adapts to different production requirements and allows for easy integration into existing manufacturing setups. - Conveyor and Gripper Type:

The system offers flexibility in handling with both conveyor and gripper types, accommodating different material handling preferences based on the production environment. - Accuracy up to 2.7um/pixel:

Achieving high precision, the machine boasts an accuracy of up to 2.7 micrometers per pixel, ensuring reliable inspection results even for minute features. - Centralized Recipe Management System:

Streamlining operations, the centralized recipe management system facilitates efficient configuration and management of inspection parameters for various wirebond and die configurations. - Multiple Reject Handling (Emap, Wire Breaker, Wire Cut, Laser Cut, Puncher):

The machine offers diverse reject handling options, including Emap, Wire Breaker, Wire Cut, Laser Cut, and Puncher, providing flexibility in dealing with identified defects. - Throughput up to 30K UPH:

With an impressive throughput of up to 30,000 units per hour (UPH), the Wirebond AOI Machine ensures rapid and efficient inspection, contributing to high-volume production processes.

Application

-

Post Die Bond/Wirebond Inspection:

The primary application of the Wirebond AOI Machine is in post die bond/wirebond inspection, ensuring the integrity and quality of wirebond connections after the bonding processes.

.png)