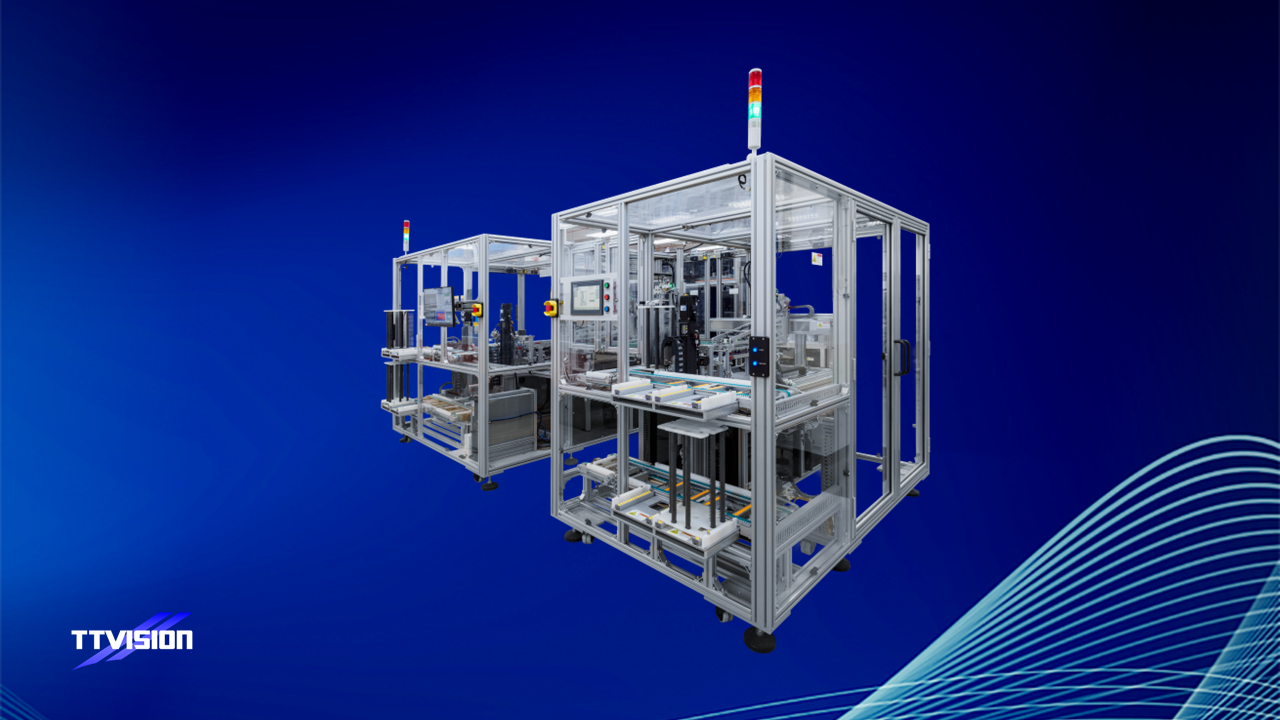

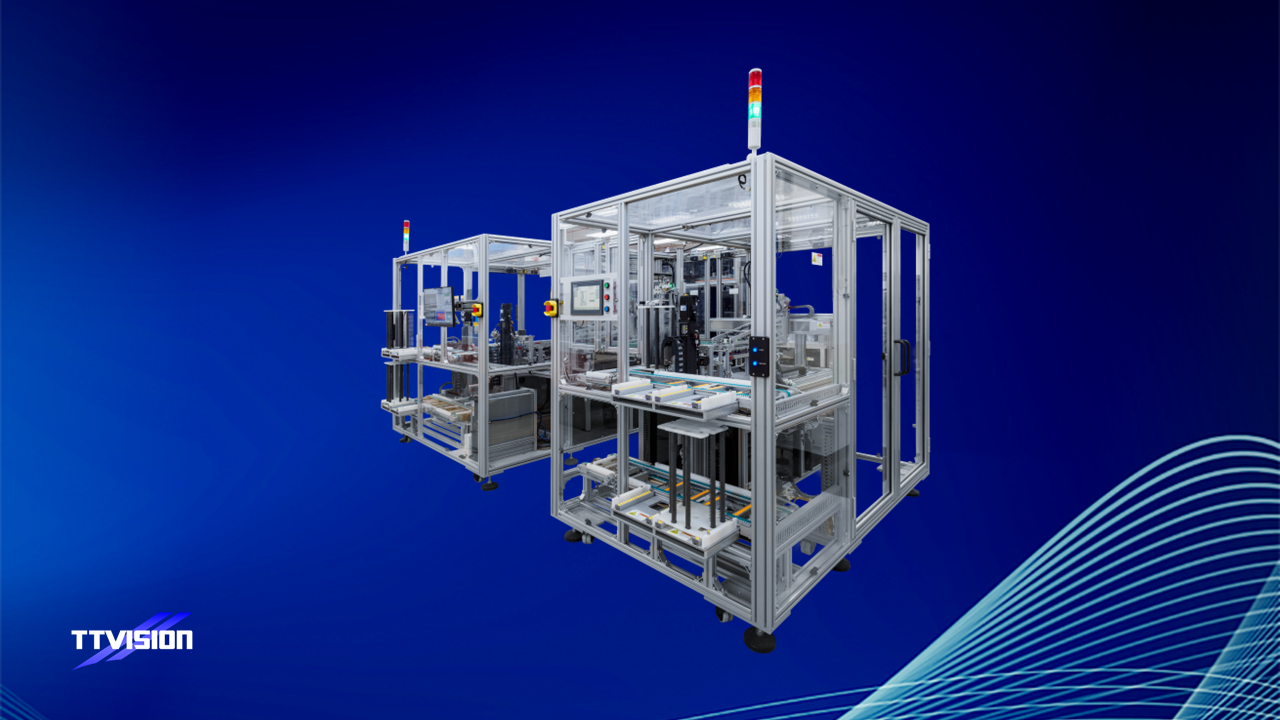

BSG Automation

Product image

BSG Automation

Description

Designed for the demanding requirements of modern solar cell production, this solution delivers exceptional wafer quality and traceability. With integrated machine vision, broken wafer rejection, and barcode/RFID tracking, it guarantees only qualified wafers proceed through.

Features

- Uninterrupted Wafer Flow:

The Cassette Loader ensures a smooth and steady stream of wafers directly into the BSG tool, eliminating bottlenecks and maximizing production uptime. - Pinpoint Wafer Transfer:

The Elevator is designed to accurately index and discharge wafers, guaranteeing flawless integration into production line. - Flawless Wafer Alignment:

Achieve perfect alignment every time. Our advanced Aligner precisely positions wafers before they enter the main tool, boosting accuracy and minimizing errors. - Zero Downtime from Broken Wafers:

Our system automatically detects and rejects broken wafers, while a smart buffer station maintains continuous loading, keeping your production running smoothly. - 100% Wafer Inspection:

Every single wafer undergoes automated machine vision inspection, ensuring only the highest quality materials proceed through your line. - Quality You Can Trust:

Defective wafers are automatically rejected, guaranteeing that only qualified wafers reach the output cassette, enhancing the overall quality of your final product. - Maximize Uptime:

Our Dual Lane Output Conveyor minimizes downtime during maintenance or cassette changes, ensuring continuous operation and maximizing throughput. - Full Traceability:

Gain complete control with our Barcode and RFID reader that tracks each wafer and links it to the cassette ID, providing full traceability for production process. - Effortless Cassette Management:

Our innovative Two-tier Cassette Conveyor Buffer and Elevator System ensures efficient loading and continuous replenishment of empty cassettes, simplifying workflow. - Adaptable to Needs:

Designed for flexibility, our equipment features automatic conversion to handle various production recipes, allowing you to quickly adapt to changing demands.

.png)